For a few years now, the term Industry 4.0 has been playing more and more loudly to refer to the great advances that this sector is experiencing, and which some already define as the fourth Industrial Revolution. It is a series of profound changes in the organization of the means of production, which will experience its great momentum starting in the second decade of the 21st century.

If in the third Industrial Revolution computing and automation were the protagonists, in Industry 4.0 the central elements will be now emerging technologies: artificial intelligence, use of Big Data, robotics and immersive solutions (virtual reality and augmented reality). It is therefore a combination of cutting-edge technologies and data analysis with advanced manufacturing techniques and processes. The most representative features of this new era will be smart connections.

In the field of immersive technologies, augmented reality (AR) gives users the opportunity to experience an enriched world from an informational plan, by superimposing virtual elements on the real world. In this way, the user can be in contact with the physical environment that surrounds him and receive data or statistics in real time that provide added value.

For the new environment in which Industry 4.0 is going to develop, RA will bring many advantages. Let’s look at some cases that have already been successfully applied in different sectors.

Logistics

The National Health Service of the United Kingdom is a giant that operates throughout the British territory with the logistical challenges that this implies and the enormous costs that it has to face when any failure occurs in the process of distribution of materials and medicines .

To reduce this problem in its internal chain, in 2018 a successful pilot program began between the public institution Leeds Teaching Hospitals NHS Trust and the company Scandit, specialized in supply chain solutions. Scandit uses AR, along with other machine learning technologies, to capture, track and collate inventory and patient data. According to the institution’s public reports, “a 95% improvement in cost savings and time efficiency was detected from implementing Scandit software in 114 departments as part of the Scan-4-Safety initiative of the government of the UK”.

“Healthcare workers have incredibly limited time and new ways are needed to free staff from inefficient tasks such as searching for a certain product or material,” said Samuel Mueller, CEO of Scandit. Thanks to augmented reality, workers, with the simple help of a mobile device, can locate the location of any item in their warehouses in a few seconds.

AR’s ability to help logistics personnel collect, process, and record data with greater precision and speed is a massive efficiency engine within the supply chain and logistics space.

Real-time information

A really incredible use of augmented reality is the possibility of providing relevant information for the technicians and workers of a company, allowing them to see data or even instructions in real time.

It is also suitable for providing technicians with a diagnosis of a machine problem going through, giving them the opportunity to view the user guide or even contact an expert for live assistance.

Large companies, such as Airbus, together with the company Innovae, have implemented it in their processes to improve information display systems for planned operations and locate defects in the production environment. Using different devices (glasses, tablets …), technicians can manipulate a digital model of the aircraft and access the different sections to explore work orders and their status, and to incorporate detected defects and incidents.

Training and prevention

Another great advantage AR brings to Industry 4.0 is the ability to improve industrial training and learning while reducing risks and costs.

Preventive training for qualified workers is an increasingly important challenge for companies due to its complexity and risks, which implies high costs and long processes. These procedures cannot be learned simply from a manual, and in addition, face-to-face training is limited by all kinds of conditions.

AR technology allows operators to detect risk situations in a simple way, improving the perception of preventive detection and generating greater awareness of its consequences.

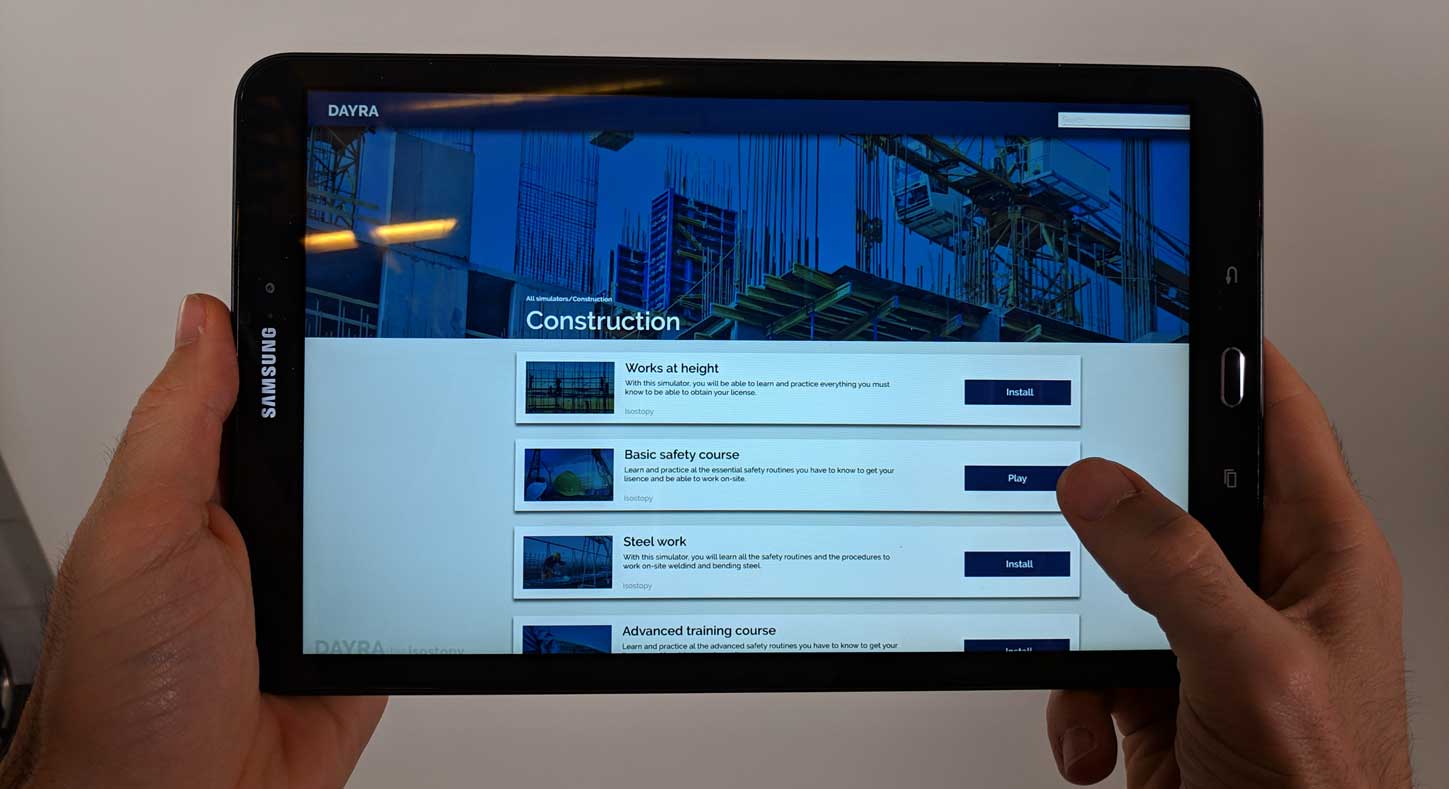

After investigating the possibilities that immersive technologies can bring to industrial training, Isostopy realized the great potential of virtual simulators in the learning process, thanks to the implementation of hyper-realistic environments. This has materialized in the development of various applications for a multinational aimed at the preventive training of its carriers.

The Dayra platform has also recently come to light, which, through a subscription model, will allow companies of different nature to access this cutting-edge training for a fraction of its cost, with the consequent savings for the company and, above all, the improvement in the quality of training for its employees and increased safety and efficiency in their daily work. In short, it is a virtual training platform, which allows workers to experience, for example, risk situations in a totally safe environment, improving their perception, which facilitates and speeds up their training. This platform was presented at the Creative Business Cup 2019 where it reached the end of the project competition with the greatest market projection.